- Home

- About

- Services

- Tools & Resources

- Client Info

- Request Info

- Carrier Tools

- Contact Us

- Get a Quote

- Français

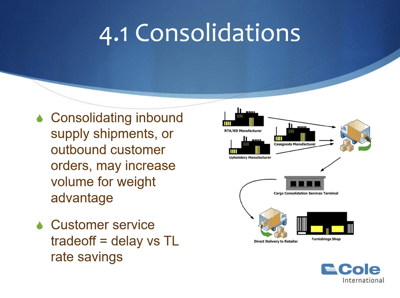

Consolidation and cross-docking can help increase efficiencies and lower costs for shippers.

Consolidation combines several smaller shipments into one larger load. For example, a furniture retailer might consolidate small shipments from a Ready-To-Assemble (RTA) or Knock Down (KD) furniture manufacturer, a casegoods manufacturer, and an upholstery manufacturer into one less expensive full truckload, rather than three separate LTL (Less Than Load) deliveries.

Consolidation combines several smaller shipments into one larger load. For example, a furniture retailer might consolidate small shipments from a Ready-To-Assemble (RTA) or Knock Down (KD) furniture manufacturer, a casegoods manufacturer, and an upholstery manufacturer into one less expensive full truckload, rather than three separate LTL (Less Than Load) deliveries.

Consolidation can:

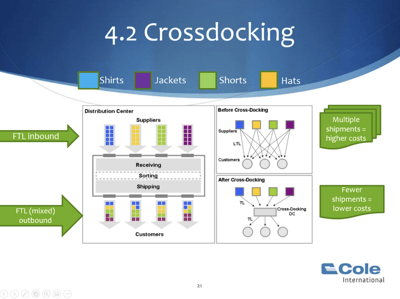

Cross-docking is the process of receiving product, sorting it at the warehouse, and shipping it out without putting it into storage.

Cross-docking is the process of receiving product, sorting it at the warehouse, and shipping it out without putting it into storage.

For example, four full truckloads each with one commodity, such as shirts, hats, coats and pants arrive to the warehouse.

The loading dock is used as a staging area where incoming shipments are quickly transitioned into outgoing shipments, eliminating the need to put the stock in storage and take up space in the warehouse.

The four single-commodity truckloads are sorted into four mixed-commodity truckloads, each full of shirts, hats, coats and pants delivered to a clothing retailer.

Instead of sixteen potential deliveries to four retailers, you’ll have four deliveries and lower costs.

Cross-docking can:

As proven best practices, consolidation and cross-docking can improve your supply chain’s performance and reduce your operations costs.

Reach out to our Freight experts today to learn more about maximizing your delivery performance and efficiency.

Information provided by: Freight Dept. - Cole International

Learn more about our freight services.

Making you aware. It’s what we do.